DCB

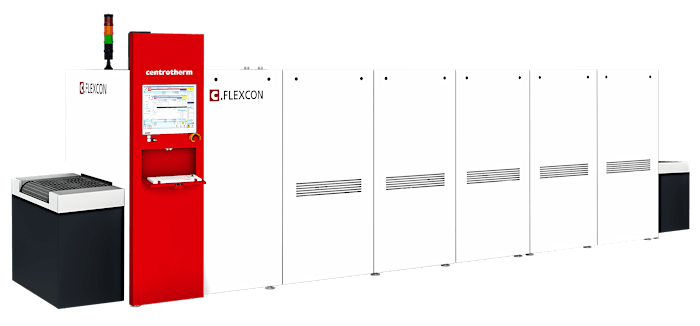

Muffle furnace for Direct Copper Bonding (DCB)

The c.DCB conveyor furnace is especially designed for direct copper bonding (DCB) applications. The system provides a high process capability and ensures an economic and efficient production.

A PLC system with bus connection monitors and controls all relevant process parameters. Data logging of process data for documentation and quality management complements the system.

Gas purity and gas flow inside the process channel play a central role to the product quality. All c.DCB furnaces are characterized by a gas tight muffle with excellent temperature and process gas control.

Processes

- Direct Copper Bonding

Options

- Profiling system with thermocouple

Sales Semiconductor & Microelectronics

Tel. +49 7344 918 6794

E-Mail

Find us at

CS MANTECH

JW Marriott Starr Pass Resort | Tucson, Arizona, USAFeatures & Benefits

- Excellent cross-temperature uniformity (<1%)

- Easy temperature profile adjustment by separate controlled heating zones

- Independent gas system for N2 curtain and N2 process atmosphere

- Process muffle tensioner

- Conveyor belt tightener

- Oxygen concentration analyzer

- O2 controller with MFC for bonding and preheating area

- Type S thermocouples

- Manual belt wheel enables belt transport in case of power failure

- Active cooling of housing

High process capability

Gas tight muffle

Low total CoO