SINGLE PLATE

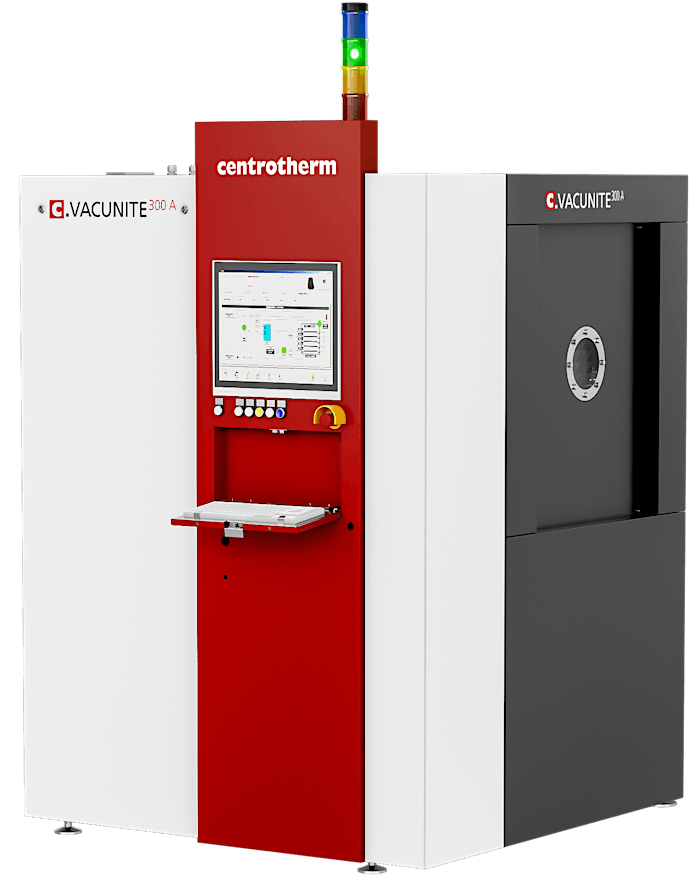

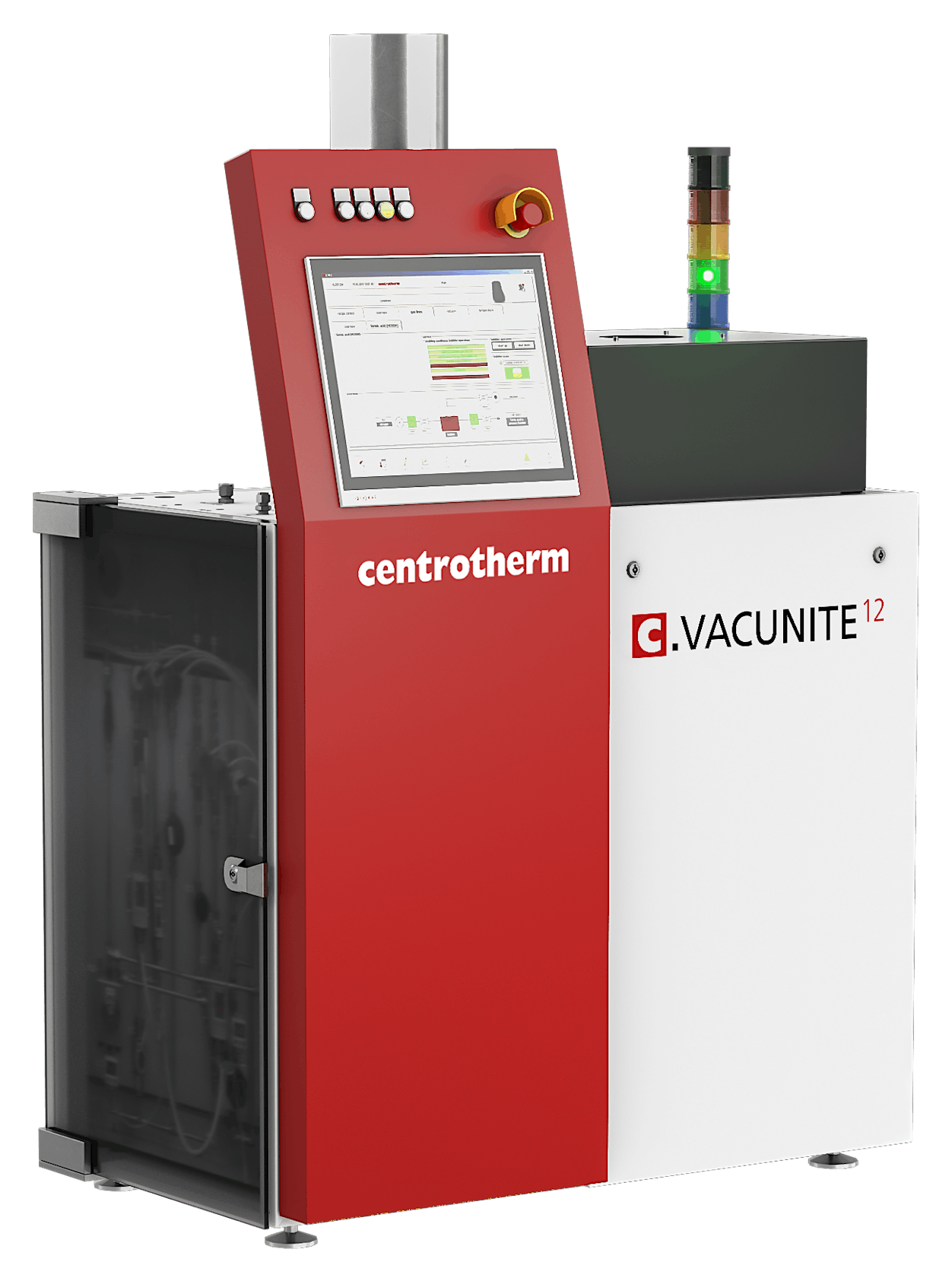

Vacuum soldering systems for R&D and pilot scale production

The centrotherm c.VACUNITE contact heat system platform covers a wide range of thermal vacuum applications. The versions 24, 12 and 6 are designed for process performance-based R&D and pilot scale production. In the field of vacuum soldering the systems meet highest requirements of voidless soldering for Advanced Packaging and Power Semiconductor applications. The void-affected area can be reduced to less than 1% whereas common reflow soldering systems range at 5%.

c.VACUNITE systems ensure fast heat-up and cool-down rates for short cycle times and reach temperatures up to 450 °C.

c.VACUNITE vacuum soldering systems allow processes under pure and oxygen-free atmospheres and provide surface activation with 100% hydrogen (H2), formic acid (HCOOH) or forming gas (N2H2). All systems are suited for 100% paste and flux.

The process control computer is equipped with a user-friendly touch screen for operating, process profile editing and recipe storing. Accessibility through Ethernet and USB interfaces allows connection with printers, external storage devices and remote access.

Processes

- Power semiconductor applications

- Advanced packaging

- Hybrid microelectronic assemblies

- Optoelectronic packaging

- Hermetic package sealing

- Wafer level packaging

- UHB LED packaging

- MEMS package sealing

- Glass bonding

- Copper annealing

- Thermal processes in various atmospheres

- Inert gas | Annealing | Oxidation

Options

- Pure hydrogen (H2)

- Vacuum system with dry pump

- Customized MES interface

Sales Semiconductor & Microelectronics

Tel. +49 7344 918 6794

E-Mail

Find us at

CS MANTECH

JW Marriott Starr Pass Resort | Tucson, Arizona, USAFeatures & Benefits

- Excellent temperature uniformity ±0.5%

- 100% suitable for paste and flux

- Independent and separately controllable gas lines

- Flux management

- Remote access for service

- Cooling water supply by open water cooling system or domestic water supply

- Safety PLC

- Maintenance friendly design for high uptime

HCOOH

100% paste and flux

Hydrogen capability

Automated operation