MULTI PLATE

Most versatile multi plate vacuum soldering systems

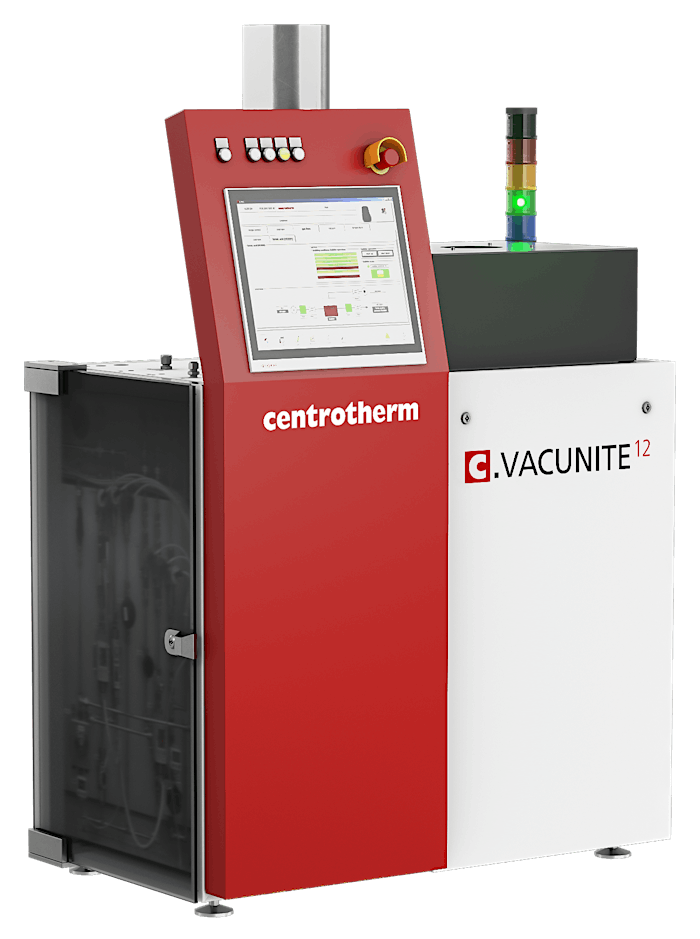

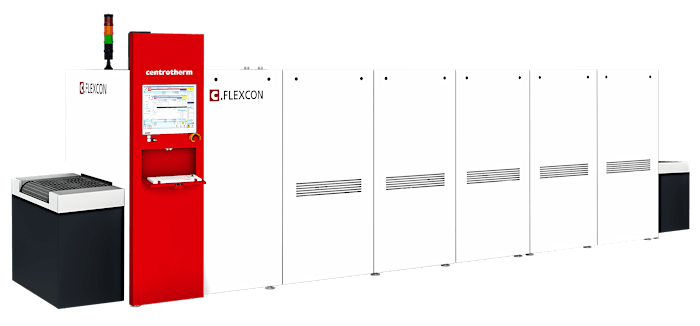

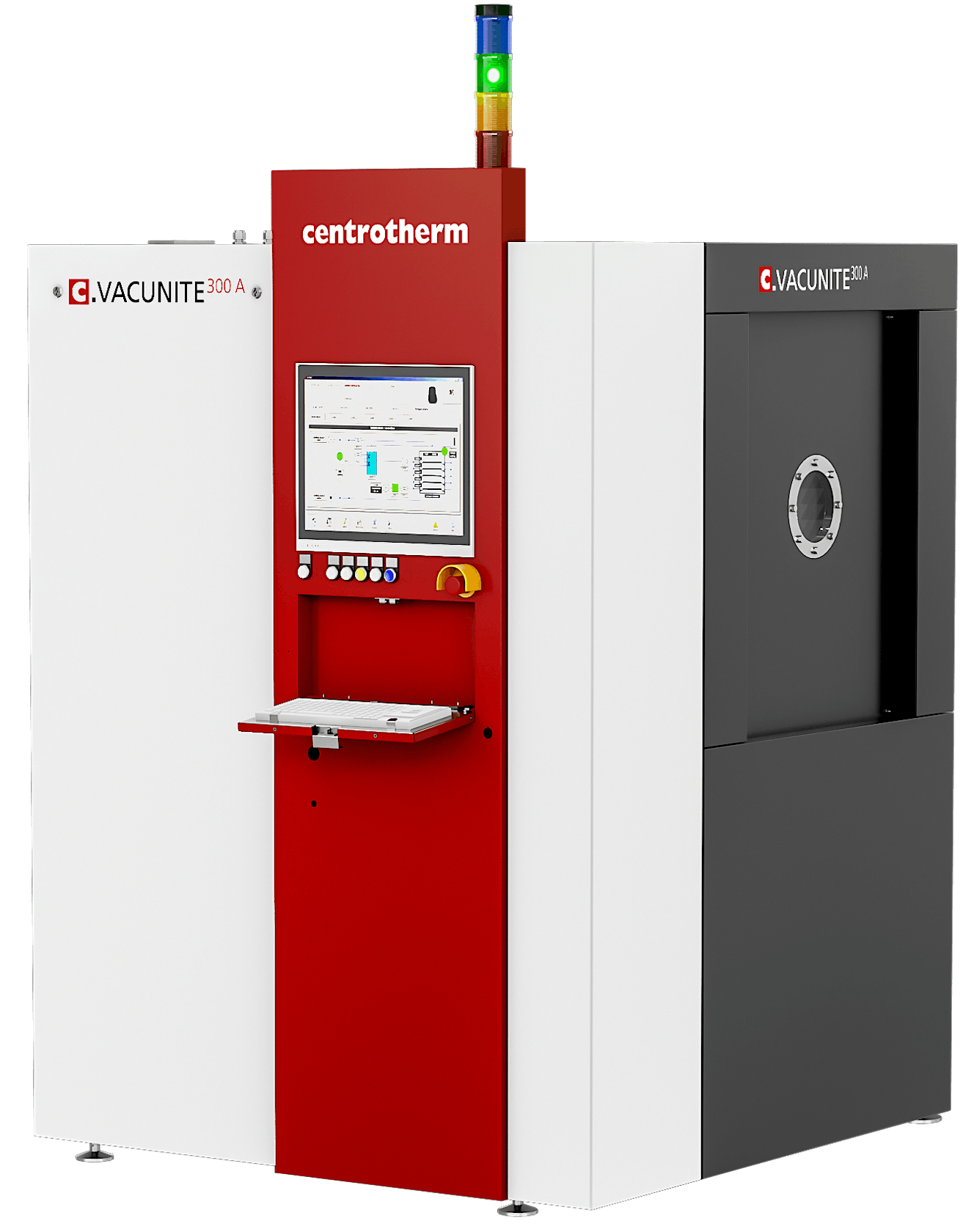

The centrotherm c.VACUNITE 300 and 180 multi plate vacuum soldering systems are designed for thermal vacuum-based processing of various materials in high-volume production. The systems meet highest requirements of ultra-clean voidless soldering for advanced packaging and power semiconductor applications. With c.VACUNITE 300A, which is equipped with an automated door closure centrotherm provides an excellent solution for fully automated production lines.

Depending on the field of application the systems ensure fast heat-up and cool-down rates for short cycle times and large processed area per hour while reaching temperatures up to 650 °C.

c.VACUNITE systems allow processes under pure and oxygen-free atmospheres and provide surface activation with 100% hydrogen (H2), formic acid (HCOOH) or forming gas (N2H2).

The void-affected area can be reduced to less than 1% whereas common reflow soldering systems range at 5%.

The process control computer is equipped with a user-friendly touch screen for operating, process profile editing and recipe storing. Accessibility through Ethernet and USB interfaces allows connection with printers, external storage devices and remote access.

Processes

- Power semiconductor applications

- Advanced packaging

- Hybrid microelectronic assemblies

- Optoelectronic packaging

- Hermetic package sealing

- Wafer level packaging

- UHB LED packaging

- MEMS package sealing

- Glass bonding

- Copper annealing

- Thermal processes in various atmospheres

- Inert gas | Annealing | Oxidation

Options

- Pure hydrogen (H2)

- Integrated HCOOH bubbler

- Vacuum system with dry pump

- Customized MES interface

- 6 thermocouples for surface temperature recording

Sales Semiconductor & Microelectronics

Tel. +49 7344 918 6794

E-Mail

Find us at

CS MANTECH

JW Marriott Starr Pass Resort | Tucson, Arizona, USAFeatures & Benefits

- Excellent temperature uniformity ±0.5%

- Independent and separately controlled gas lines

- Particle-free

- Uptime > 98.5%

- Cooling water supply by open water cooling system or domestic water supply

- Safety PLC

- Controllable via 19“ touch screen

- Remote access for service

- Maintenance friendly design for high uptime

HCOOH

Hydrogen capability

Automated operation